<pubnumber> 736B94001

736B94001 </pubnumber>

<title>Guidance Manual for Selecting Protective Clothing for Agricultural Pesticides Operations</title>

<pages>354</pages>

<pubyear>1994</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<operator>BO</operator>

<scandate>04/07/97</scandate>

<origin>hardcopy</origin>

<type>single page tiff</type>

<keyword>ppe pesticide clothing pesticides glove fabrics permeation protective protection gloves heat materials chemical rubber face cotton appendices laundering material stress</keyword>

Guidance Manual for

Selecting Protective Clothing

for Agricultural Pesticides

Operations

Contract No. 68-C9-0037

Work Assignment 0-20

Project Officer

Uwe Frank

Risk Reduction Engineering Laboratory

U.S. Environmental Protection Agency

Edison, New Jersey 08837-3679

Risk Reduction Engineering Laboratory

Office Of Research And Development

U.S. Environmental Protection Agency

Cincinnati, Ohio 45268

image:

</pubnumber>

<title>Guidance Manual for Selecting Protective Clothing for Agricultural Pesticides Operations</title>

<pages>354</pages>

<pubyear>1994</pubyear>

<provider>NEPIS</provider>

<access>online</access>

<operator>BO</operator>

<scandate>04/07/97</scandate>

<origin>hardcopy</origin>

<type>single page tiff</type>

<keyword>ppe pesticide clothing pesticides glove fabrics permeation protective protection gloves heat materials chemical rubber face cotton appendices laundering material stress</keyword>

Guidance Manual for

Selecting Protective Clothing

for Agricultural Pesticides

Operations

Contract No. 68-C9-0037

Work Assignment 0-20

Project Officer

Uwe Frank

Risk Reduction Engineering Laboratory

U.S. Environmental Protection Agency

Edison, New Jersey 08837-3679

Risk Reduction Engineering Laboratory

Office Of Research And Development

U.S. Environmental Protection Agency

Cincinnati, Ohio 45268

image:

Disclaimer

The information in this document has been funded wholly or in part by the

United States Environmental Protection Agency (EPA) under Contract No.

68-C9-0037 to Arthur D. Little, Inc. It has been subjected to the Agency's

peer and administrative review, and it has been approved for publication as

an EPA document. Mention of trade names or commercial products does

not constitute endorsement or recommendation for use.

image:

Disclaimer

The information in this document has been funded wholly or in part by the

United States Environmental Protection Agency (EPA) under Contract No.

68-C9-0037 to Arthur D. Little, Inc. It has been subjected to the Agency's

peer and administrative review, and it has been approved for publication as

an EPA document. Mention of trade names or commercial products does

not constitute endorsement or recommendation for use.

image:

Foreword

Today's rapidly developing and changing technologies and industrial prod-

ucts and practices frequently carry with them the increased generation of

materials that, if improperly dealt with, can threaten both public health and

the environment. The U.S. Environmental Protection Agency (EPA) is ,

charged by Congress with protecting the Nation's land, air, and water

resources. Under a mandate of national environmental laws, the agency

strives to formulate and implement actions leading to a compatible balance

between human activities and the ability of natural systems to define our

environmental problems, measure the impacts, and search for solutions.

The Risk Reduction Engineering Laboratory is responsible for planning,

implementing, and managing research, development, and demonstration

programs to provide an authoritative, defensible engineering basis in support

of the policies, programs, and regulations of the EPA with respect to drink-

ing water, wastewater, pesticides, toxic substances, solid and hazardous

wastes, and Superfund-related activities.

Under the Federal Insecticide, Fungicide, and Rodenticide Act (FTFRA),

the EPA and, more specifically, its Office of Pesticides Programs (OPP) is

mandated to protect the health and safety of agricultural pesticide handlers

and agricultural workers who may be exposed to pesticides. In support of

this mission, this manual consolidates and extends information on the per-

formance, availability, and limitations of personnel protective equipment

required for pesticide handlers. Based on this information, guidance is

developed for the selection, use, and reuse of such equipment. This publica-

tion provides a vital communications link between the researcher and the

user community.

E. Timothy Oppelt, Director

Risk Reduction Engineering Laboratory

image:

Foreword

Today's rapidly developing and changing technologies and industrial prod-

ucts and practices frequently carry with them the increased generation of

materials that, if improperly dealt with, can threaten both public health and

the environment. The U.S. Environmental Protection Agency (EPA) is ,

charged by Congress with protecting the Nation's land, air, and water

resources. Under a mandate of national environmental laws, the agency

strives to formulate and implement actions leading to a compatible balance

between human activities and the ability of natural systems to define our

environmental problems, measure the impacts, and search for solutions.

The Risk Reduction Engineering Laboratory is responsible for planning,

implementing, and managing research, development, and demonstration

programs to provide an authoritative, defensible engineering basis in support

of the policies, programs, and regulations of the EPA with respect to drink-

ing water, wastewater, pesticides, toxic substances, solid and hazardous

wastes, and Superfund-related activities.

Under the Federal Insecticide, Fungicide, and Rodenticide Act (FTFRA),

the EPA and, more specifically, its Office of Pesticides Programs (OPP) is

mandated to protect the health and safety of agricultural pesticide handlers

and agricultural workers who may be exposed to pesticides. In support of

this mission, this manual consolidates and extends information on the per-

formance, availability, and limitations of personnel protective equipment

required for pesticide handlers. Based on this information, guidance is

developed for the selection, use, and reuse of such equipment. This publica-

tion provides a vital communications link between the researcher and the

user community.

E. Timothy Oppelt, Director

Risk Reduction Engineering Laboratory

image:

image:

image:

Abstract

The Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and its

amendments provide for the protection of the health and safety of farmers

and farm workers who may be exposed to pesticides. Reduced contact with

the active ingredients and other components of pesticides is particularly

important for people who mix, load, and apply pesticides. Personal protec-

tive equipment is one means by which contact with potentially harmful

pesticides can be minimized.

The Guidance Manual summarized here consolidates and extends literature

information on the barrier effectiveness of protective materials to pesticides,

the effect of personal protective equipment (PPE) on the productivity of

pesticide handlers, heat stress associated with the use of PPE, and methods

for decontamination of PPE. The Guidance Manual contains extensive

appendices describing commercially available products.

image:

Abstract

The Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and its

amendments provide for the protection of the health and safety of farmers

and farm workers who may be exposed to pesticides. Reduced contact with

the active ingredients and other components of pesticides is particularly

important for people who mix, load, and apply pesticides. Personal protec-

tive equipment is one means by which contact with potentially harmful

pesticides can be minimized.

The Guidance Manual summarized here consolidates and extends literature

information on the barrier effectiveness of protective materials to pesticides,

the effect of personal protective equipment (PPE) on the productivity of

pesticide handlers, heat stress associated with the use of PPE, and methods

for decontamination of PPE. The Guidance Manual contains extensive

appendices describing commercially available products.

image:

image:

image:

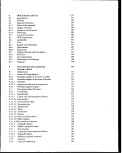

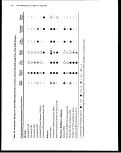

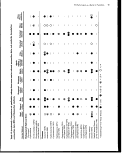

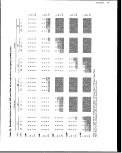

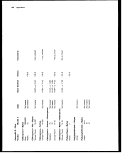

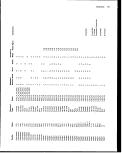

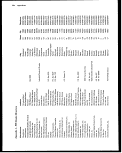

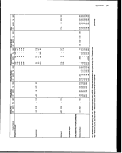

Table of Contents

1 Introduction 1

1.1 Pesticide Regulation 1

1.1.1 Current Role of the Environmental Protection Agency 1

1.1.2 Office of Pesticide Programs Mission 1

1.1.3 Office of Pesticide Programs Involvement with Personal

Protective Equipment 1

1.1.4 Office of Research and Development's Personnel Protection

Program 2

1.2 Purpose of Guidance Manual 3

1.3 Guidance Manual Content 3

2 Handling Pesticides 5

Section in Brief

2.1 Introduction 5

2.2 Handling Activities 5

2.2.1 Mixing pesticides 5

2.2.2 Loading pesticides 6

2.2.3 Applying pesticides 6

2.3 Formulation Characteristics 6

2.3.1 Form 7

2.3.2 Toxicity 7

2.3.3 Concentration 8

2.3.4 Additives and inert ingredients 8

2.4 Exposure Scenarios 8

2.4.1 On foot 8

2.4.2 On a vehicle 9

2.4.3 By air 10

2.4.4 Exposure scenarios deserving special consideration 10

2 A A.I Engineering Controls 10

2.4.4.2 Enclosed Areas 10

2.5 Environmental Factors 10

2.5.1 Weather 10

2.5.2 Terrain 11

2.6 Facility Amenities 11

2.6.1 Decontamination areas 11

2.6.2 Health monitoring 12

image:

Table of Contents

1 Introduction 1

1.1 Pesticide Regulation 1

1.1.1 Current Role of the Environmental Protection Agency 1

1.1.2 Office of Pesticide Programs Mission 1

1.1.3 Office of Pesticide Programs Involvement with Personal

Protective Equipment 1

1.1.4 Office of Research and Development's Personnel Protection

Program 2

1.2 Purpose of Guidance Manual 3

1.3 Guidance Manual Content 3

2 Handling Pesticides 5

Section in Brief

2.1 Introduction 5

2.2 Handling Activities 5

2.2.1 Mixing pesticides 5

2.2.2 Loading pesticides 6

2.2.3 Applying pesticides 6

2.3 Formulation Characteristics 6

2.3.1 Form 7

2.3.2 Toxicity 7

2.3.3 Concentration 8

2.3.4 Additives and inert ingredients 8

2.4 Exposure Scenarios 8

2.4.1 On foot 8

2.4.2 On a vehicle 9

2.4.3 By air 10

2.4.4 Exposure scenarios deserving special consideration 10

2 A A.I Engineering Controls 10

2.4.4.2 Enclosed Areas 10

2.5 Environmental Factors 10

2.5.1 Weather 10

2.5.2 Terrain 11

2.6 Facility Amenities 11

2.6.1 Decontamination areas 11

2.6.2 Health monitoring 12

image:

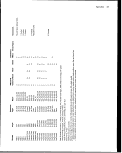

2.7

Conclusion

13

3 Chemical-Resistant PPE Products IS

Section in Brief

3.1 Introduction 15

3.2 Hand and Forearm Protection 15

3.2.1 Glove manufacturing methods and materials 15

3.2.1.1 Latex System 16

3.2.1.2 Solvent-Based System 17

3.2.1.3 Plastisol System 17

3.2.1.4 Lining 18

3.2.2 Design features 18

3.2.2.1 Thickness 19

3.2.2.2 Glove Size 19

3.2.2.3 Length 20

3.2.2.4 Liners 20

3.2.2.5 Cuff Style 21

3.2.2.6 Grip Type 21

3.2.3 Sleeves 21

3.3 Foot Protection 22

3.3.1 Introduction 22

3.3.2 Boots 22

3.3.3 Shoe covers 22

3.4 Head Protection 22

3.4.1 Hats 22

3.4.2 Hoods 23

3.5 Frontal Protection 23

3.6 Body Protection 24

3.6.1 Woven cotton and cotton/polyester 24

3.6.2 Nonwoven fabrics and fabrics containing microporous PTFE 24

3.6.2.1 Nonwoven fabrics 24

3.6.2.2 Fabrics containing microporous PTFE 26

3.6.3 Plastic or rubber film/sheet, film-coated or -laminated woven or

nonwoven fabrics 26

3.7 Physical Characteristics 27

References 30

4 PPE Performance as a Barrier to Pesticides 31

Section in Brief

4.1 Overview 31

4.2 Measures of Chemical Resistance 32

4.2.1 Penetration 32

4.2.1.1 ASTM F903—Resistance of protective clothing materials

to penetration by liquids 3 3

4.2.1.2 ISO 6530—Clothing for limited protection against dangerous

liquid chemicals—resistance to penetration—marking 3 3

4.2.1.3 AATCC 22-1985—Water Repellency: Spray Test 33

4.2.2 Permeation 33

4.2.2.1 Theory 33

4.2.2.2 Permeation Test Methods 35

image:

2.7

Conclusion

13

3 Chemical-Resistant PPE Products IS

Section in Brief

3.1 Introduction 15

3.2 Hand and Forearm Protection 15

3.2.1 Glove manufacturing methods and materials 15

3.2.1.1 Latex System 16

3.2.1.2 Solvent-Based System 17

3.2.1.3 Plastisol System 17

3.2.1.4 Lining 18

3.2.2 Design features 18

3.2.2.1 Thickness 19

3.2.2.2 Glove Size 19

3.2.2.3 Length 20

3.2.2.4 Liners 20

3.2.2.5 Cuff Style 21

3.2.2.6 Grip Type 21

3.2.3 Sleeves 21

3.3 Foot Protection 22

3.3.1 Introduction 22

3.3.2 Boots 22

3.3.3 Shoe covers 22

3.4 Head Protection 22

3.4.1 Hats 22

3.4.2 Hoods 23

3.5 Frontal Protection 23

3.6 Body Protection 24

3.6.1 Woven cotton and cotton/polyester 24

3.6.2 Nonwoven fabrics and fabrics containing microporous PTFE 24

3.6.2.1 Nonwoven fabrics 24

3.6.2.2 Fabrics containing microporous PTFE 26

3.6.3 Plastic or rubber film/sheet, film-coated or -laminated woven or

nonwoven fabrics 26

3.7 Physical Characteristics 27

References 30

4 PPE Performance as a Barrier to Pesticides 31

Section in Brief

4.1 Overview 31

4.2 Measures of Chemical Resistance 32

4.2.1 Penetration 32

4.2.1.1 ASTM F903—Resistance of protective clothing materials

to penetration by liquids 3 3

4.2.1.2 ISO 6530—Clothing for limited protection against dangerous

liquid chemicals—resistance to penetration—marking 3 3

4.2.1.3 AATCC 22-1985—Water Repellency: Spray Test 33

4.2.2 Permeation 33

4.2.2.1 Theory 33

4.2.2.2 Permeation Test Methods 35

image:

4.2.2.2.1 Overview 35

4.2.2.2.2 Continuous exposure 36

4.2.2.2.3 Intermittent exposure 38

4.2.2.3 Factors affecting permeation test results 39

4.2.3 Degradation 42

4.3 Arm/Hand Protection 43

4.3.1 Introduction 43

4.3.2 Pesticide formulation types 43

4.3.3 Solvent permeation 44

4.3.4 Pesticide formulation permeation 49

4.3.4.1 EPA pesticide permeation study 49

4.3.4.2 Harpenden tracer study 57

4.3.5 General recommendations for glove selection 63

4.4 Body Protection 70

4.4.1 Introduction 70

4.4.2 Woven cotton and cotton/polyester fabrics 70

4.4.2.1 Effect of pesticide amount 70

4.4.2.2 Effect of fabric type 71

4.4.2.3 Effect of fabric finish 72

4.4.2.4 Effect of laundering 74

4.4.2.5 Effect of temperature and humidity 74

4.4.3 Nonwoven fabrics, including microporous PTFE 74

4.4.4 Film-coated or -laminated woven or nonwoven fabrics 75

4.4.5 Garment design 76

References 78

5 Eye and Face Protection 83

Section in Brief

5.1 Introduction 83

5.2 OSHA Eye and Face Protection Requirements 83

5.3 ANSI Z87.1-1989 84

5.4 Selection Guidance , 84

5.5 Commercially Available Products 86

5.5.1 Cover goggles-indirect ventilation and no ventilation 86

5.5.1.1 Lens material 87

5. 5; 1.2 UV protection 87

5.5.1.3 Anti-fogging 87

5.5.1.4 Tinting 87.

5.5.1.5 Scratch resistance 87

5.5.1.6 Prescription glasses 87

5.5.2 Cup goggles-indirect ventilation 88

5.5.3 Face shields 88

5.5.4 Headbands 88

5.5.5 Use and maintenance 88

5.5.6 Respirators 89

References

90

image:

4.2.2.2.1 Overview 35

4.2.2.2.2 Continuous exposure 36

4.2.2.2.3 Intermittent exposure 38

4.2.2.3 Factors affecting permeation test results 39

4.2.3 Degradation 42

4.3 Arm/Hand Protection 43

4.3.1 Introduction 43

4.3.2 Pesticide formulation types 43

4.3.3 Solvent permeation 44

4.3.4 Pesticide formulation permeation 49

4.3.4.1 EPA pesticide permeation study 49

4.3.4.2 Harpenden tracer study 57

4.3.5 General recommendations for glove selection 63

4.4 Body Protection 70

4.4.1 Introduction 70

4.4.2 Woven cotton and cotton/polyester fabrics 70

4.4.2.1 Effect of pesticide amount 70

4.4.2.2 Effect of fabric type 71

4.4.2.3 Effect of fabric finish 72

4.4.2.4 Effect of laundering 74

4.4.2.5 Effect of temperature and humidity 74

4.4.3 Nonwoven fabrics, including microporous PTFE 74

4.4.4 Film-coated or -laminated woven or nonwoven fabrics 75

4.4.5 Garment design 76

References 78

5 Eye and Face Protection 83

Section in Brief

5.1 Introduction 83

5.2 OSHA Eye and Face Protection Requirements 83

5.3 ANSI Z87.1-1989 84

5.4 Selection Guidance , 84

5.5 Commercially Available Products 86

5.5.1 Cover goggles-indirect ventilation and no ventilation 86

5.5.1.1 Lens material 87

5. 5; 1.2 UV protection 87

5.5.1.3 Anti-fogging 87

5.5.1.4 Tinting 87.

5.5.1.5 Scratch resistance 87

5.5.1.6 Prescription glasses 87

5.5.2 Cup goggles-indirect ventilation 88

5.5.3 Face shields 88

5.5.4 Headbands 88

5.5.5 Use and maintenance 88

5.5.6 Respirators 89

References

90

image:

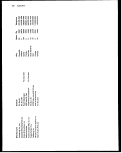

6 Effect of Personal Protective Equipment on Job

Performance 91

Section in Brief

6.1 Introduction 91

6.2 Mixer, Loader, Applicator Functions 91

6.2.1 Introduction 91

6.2.2 Dexterity and tactility 92

6.2.3 Mobility 93

6.2.4 Vision 94

6.2.4.1 Field of view 94

6.2.4.2 Visual acuity 95

6.2.5 Speech intelligibility 95

6.2.6 Relative importance of functional requirements 95

6.3 Protection Levels 96

6.4 Effects of PPE on Worker Productivity 97

6.4.1 PPE components 97

6.4.1.1 Gloves 97

6.4.1.2 Boots 99

6.4.1.3 Respirators 99

6.4.1.4 Encapsulating ensembles 99

6.4.2 PPE Ensembles 100

References 102

7 Heat Stress 103

Section in Brief

7.1 Introduction 103

7.2 Workload for Pesticide Workers 105

7.2.1 Maximum work capacity 105

7.2.2 Energy expenditure for pesticide worker tasks 105

7.3 Properties of Protective Clothing and Their Contribution

to Heat Stress 107

7.3.1 Clothing insulation 107

7.3.2 Pumping coefficient 108

7.3.3 Moisture permeability index 108

7.3.4 Permeability index ratio 109

7.3.5 Representative PPE combinations for agricultural workers 109

7.4 Work/Rest Cycles 109

7.4.1 Mathematical models 110

7.4.2 Decision rules 112

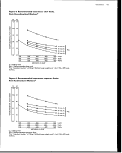

7.4.3 NIOSHWBGT decision rule 112

7.4.4 Application of NIOSH decision rule to pesticide handlers 116

7.4.4.1 Estimation of work rate 116

7.4.4.2 Estimation of WBGT 116

7.4.4.3 Adjustments to WBGT for PPE levels 125

7.4.4.4 Examples of procedure 126

7.4.4.5 Relevance to OPP 128

7.5 Summary 130

References 131

image:

6 Effect of Personal Protective Equipment on Job

Performance 91

Section in Brief

6.1 Introduction 91

6.2 Mixer, Loader, Applicator Functions 91

6.2.1 Introduction 91

6.2.2 Dexterity and tactility 92

6.2.3 Mobility 93

6.2.4 Vision 94

6.2.4.1 Field of view 94

6.2.4.2 Visual acuity 95

6.2.5 Speech intelligibility 95

6.2.6 Relative importance of functional requirements 95

6.3 Protection Levels 96

6.4 Effects of PPE on Worker Productivity 97

6.4.1 PPE components 97

6.4.1.1 Gloves 97

6.4.1.2 Boots 99

6.4.1.3 Respirators 99

6.4.1.4 Encapsulating ensembles 99

6.4.2 PPE Ensembles 100

References 102

7 Heat Stress 103

Section in Brief

7.1 Introduction 103

7.2 Workload for Pesticide Workers 105

7.2.1 Maximum work capacity 105

7.2.2 Energy expenditure for pesticide worker tasks 105

7.3 Properties of Protective Clothing and Their Contribution

to Heat Stress 107

7.3.1 Clothing insulation 107

7.3.2 Pumping coefficient 108

7.3.3 Moisture permeability index 108

7.3.4 Permeability index ratio 109

7.3.5 Representative PPE combinations for agricultural workers 109

7.4 Work/Rest Cycles 109

7.4.1 Mathematical models 110

7.4.2 Decision rules 112

7.4.3 NIOSHWBGT decision rule 112

7.4.4 Application of NIOSH decision rule to pesticide handlers 116

7.4.4.1 Estimation of work rate 116

7.4.4.2 Estimation of WBGT 116

7.4.4.3 Adjustments to WBGT for PPE levels 125

7.4.4.4 Examples of procedure 126

7.4.4.5 Relevance to OPP 128

7.5 Summary 130

References 131

image:

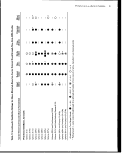

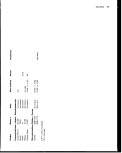

8 PPE Selection and Use

8.1 Introduction

8.2 Toxicity

8.3 Exposure Scenarios

8.3.1 Form of the pesticide

8.3.2 Degree of control

8.3.3 Duration and frequency

8.3.4 Work task

8.4 Level of Protection

8.5 PPE Performance

8.6 Availability

8.7 Cost

8.8 Impact on Productivity

8.8.1 Job function

8.8.2 Heat stress

8.9 Worker Training and Compliance

8.10 PPE Use

8.11 Decontamination

8.12 Maintenance and Storage

8.13 Disposal

9.1

9.2

9.2

9.2

9.2

9.2

9.2

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

1

2

2.1

2.2

3

1

.1.1

.1.2

.1.2.

.1.2.

,1.2.

.1.2.

.1.2.

.1.2.

.1.2.

.1.2.

.1.2.

.2.1.

.1.3

.1.4

.2

.2.1

.2.2

.2.3

.3

.4

Decontamination/ Laundering

Section in Brief

Background

Forms of Contamination

Pesticides applied in the form of solids

Pesticides applied in the form of liquids

Solutions

Aqueous emulsions and suspensions

Pesticides applied as gases

Decontamination Processes

Laundering

Introduction

Cotton and cotton/polyester fabrics

1 Introduction

2 Contamination type

3 Detergent type

4 Temperature

5 Water

,6 Timeliness

,7 Process

,8 Fiber and fabric effects

,9 Fabric finishes

.lOContamination transfer

Polyolefin fabrics

Rubber and plastic items.

Dry cleaning

Cotton and cotton/polyester fabrics

Polyolefin fabrics

Rubber and plastic materials

Aeration

Chemical treatments

137

137

139

139

139

140

140

140

140

141

141

142

147

147

147

147

148

148

148

149

151

151

152

153

153

153

153

154

154

155

155

155

155

157

157

158

158

159

159

159

160

160

160

161

161

161

162

162

162

163

image:

8 PPE Selection and Use

8.1 Introduction

8.2 Toxicity

8.3 Exposure Scenarios

8.3.1 Form of the pesticide

8.3.2 Degree of control

8.3.3 Duration and frequency

8.3.4 Work task

8.4 Level of Protection

8.5 PPE Performance

8.6 Availability

8.7 Cost

8.8 Impact on Productivity

8.8.1 Job function

8.8.2 Heat stress

8.9 Worker Training and Compliance

8.10 PPE Use

8.11 Decontamination

8.12 Maintenance and Storage

8.13 Disposal

9.1

9.2

9.2

9.2

9.2

9.2

9.2

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

9.3

1

2

2.1

2.2

3

1

.1.1

.1.2

.1.2.

.1.2.

,1.2.

.1.2.

.1.2.

.1.2.

.1.2.

.1.2.

.1.2.

.2.1.

.1.3

.1.4

.2

.2.1

.2.2

.2.3

.3

.4

Decontamination/ Laundering

Section in Brief

Background

Forms of Contamination

Pesticides applied in the form of solids

Pesticides applied in the form of liquids

Solutions

Aqueous emulsions and suspensions

Pesticides applied as gases

Decontamination Processes

Laundering

Introduction

Cotton and cotton/polyester fabrics

1 Introduction

2 Contamination type

3 Detergent type

4 Temperature

5 Water

,6 Timeliness

,7 Process

,8 Fiber and fabric effects

,9 Fabric finishes

.lOContamination transfer

Polyolefin fabrics

Rubber and plastic items.

Dry cleaning

Cotton and cotton/polyester fabrics

Polyolefin fabrics

Rubber and plastic materials

Aeration

Chemical treatments

137

137

139

139

139

140

140

140

140

141

141

142

147

147

147

147

148

148

148

149

151

151

152

153

153

153

153

154

154

155

155

155

155

157

157

158

158

159

159

159

160

160

160

161

161

161

162

162

162

163

image:

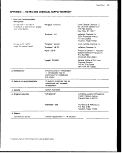

9.3.4.1 Cotton and cotton/polyester fabrics 163

9.3.4.2 Polyolefm fabrics 163

9.3.4.3 Rubber and plastic items 163

9.3.5 Sorbents 164

9.4 Current Agricultural Decontamination Practices 164

9.5 Practical Considerations 165

9.5.1 Water use 165

9.5.2 Water temperature 165

9.5.3 Dry cleaning 165

9.5.4 Waste disposal 165

9.5.5 Cost 165

9.6 Recommendations 166

References 167

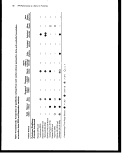

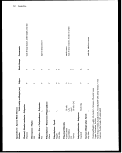

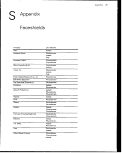

Appendices

A. Gloves 171

B. Sleeves 185

C. Footwear 191

D. Hats 197

E. Hoods 201

F. Aprons , 207

G. Aprons with sleeves 213

H. Clothing based on porous or microporous fabrics 215

I. Splash suits and rainwear 223

J. PPE vendor directory 233

K. Neat carrier solvent permeation data 237

L. Harpenden tracer study breakthrough time data 253

M. 29 CFR 1910.133 257

N. Modifications to ANSI Z87.1 261

O. Manufacturers of eye and face protective devices 263

P. Cover goggle, indirect ventilation 269

Q. Cover goggle, no ventilation 275

R. Cup goggle, ventilation 279

S. Faceshields 281

T. Laundering Tyvek® spunbonded polyolefin 283

U. From the farm chemicals handbook 291

V. Laundering guidance from Agway Corp 293

W Extension service information pertinent to decontamination 297

image:

9.3.4.1 Cotton and cotton/polyester fabrics 163

9.3.4.2 Polyolefm fabrics 163

9.3.4.3 Rubber and plastic items 163

9.3.5 Sorbents 164

9.4 Current Agricultural Decontamination Practices 164

9.5 Practical Considerations 165

9.5.1 Water use 165

9.5.2 Water temperature 165

9.5.3 Dry cleaning 165

9.5.4 Waste disposal 165

9.5.5 Cost 165

9.6 Recommendations 166

References 167

Appendices

A. Gloves 171

B. Sleeves 185

C. Footwear 191

D. Hats 197

E. Hoods 201

F. Aprons , 207

G. Aprons with sleeves 213

H. Clothing based on porous or microporous fabrics 215

I. Splash suits and rainwear 223

J. PPE vendor directory 233

K. Neat carrier solvent permeation data 237

L. Harpenden tracer study breakthrough time data 253

M. 29 CFR 1910.133 257

N. Modifications to ANSI Z87.1 261

O. Manufacturers of eye and face protective devices 263

P. Cover goggle, indirect ventilation 269

Q. Cover goggle, no ventilation 275

R. Cup goggle, ventilation 279

S. Faceshields 281

T. Laundering Tyvek® spunbonded polyolefin 283

U. From the farm chemicals handbook 291

V. Laundering guidance from Agway Corp 293

W Extension service information pertinent to decontamination 297

image:

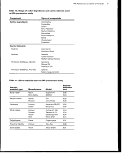

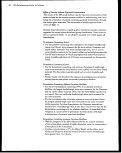

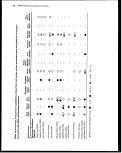

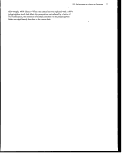

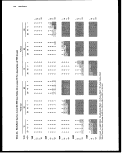

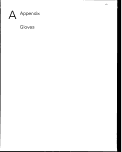

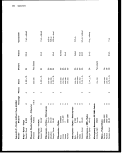

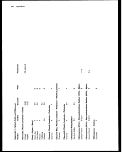

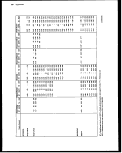

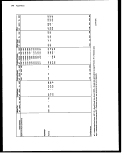

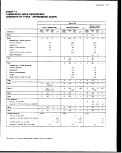

List of Figures

Figure 1. Idealization of Fickian Permeation 34

Figure 2. Concentration gradient across material as a function of time 3 5

Figure 3. Recommended heat-stress alert limits 113

Figure 4. Recommended heat-stress exposure limits 113

Figure 5. Psychrometric chart 129

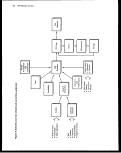

Figured. Selection and use of personal protective equipment 138

Figure 7. Guidelines for laundering pesticide-contaminated clothing 156

image:

List of Figures

Figure 1. Idealization of Fickian Permeation 34

Figure 2. Concentration gradient across material as a function of time 3 5

Figure 3. Recommended heat-stress alert limits 113

Figure 4. Recommended heat-stress exposure limits 113

Figure 5. Psychrometric chart 129

Figured. Selection and use of personal protective equipment 138

Figure 7. Guidelines for laundering pesticide-contaminated clothing 156

image:

image:

image:

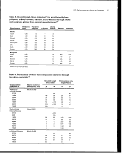

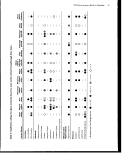

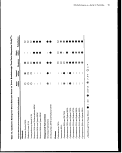

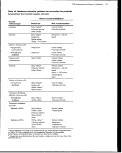

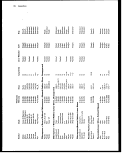

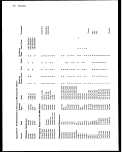

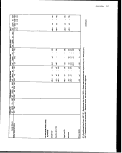

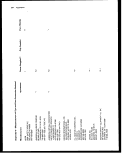

List of Tables

Table 1. Toxicity categories 7

Table 2. Recommended physical property test methods for PPE 28

TableS. Physical characteristics of glove materials 29

Table 4. Effect of thickness on the permeation of benzene through

neoprene rubber at 22°C 40

Table 5. Breakthrough times (minutes) for perchloroethylene,

p-Xylene, n-Butyl acetate, ethanol, and n-Hexane through

nitrile and neoprene gloves from several manufacturers 41

Table 6. Permeation of three two-component mixtures through

two glove materials 41

Table 7. Organic liquids used as carrier solvents in non-aqueous

solution pesticide formulations 45

Table 8. Ratings categories for qualitative summary of neat carrier

solvent permeation data 46

Table 9. Neat carrier solvent permeation table (ratings) 47

Table 10. Range of active ingredients and carrier solvents used in

EPA permeation study 51

Table 11. Glove materials used in EPA permeation study 51

Table 12. Individual ratings categories for qualitative summary

of EPA permeation data 52

Table 13. EPA study ratings 54

Table 14. Tracer ratings 59

Table 15. Sumary table 64

Table 16. Handwear selection guidance for protection for pesticide

formulations that contain organic solvents 69

Table 17. Body protection guidance 71

Table 18. Prices for hooded coveralls 76

Table 19. Selection guidance for eye and face protection 86

Table 20. Functional activities of mixers, loaders, and applications 92

Table 21. Weighting factors for functional requirements by

type of activity 96

Table 22. Protective clothing ensembles 96

Table 2 3. Increase in task time due to PPE 98

Table 24. Performance decrements as function of type of work

and protection level 101

Table 25. Overall performance decrements due to PPE 101

Table 26. Signs and Symptoms of Heat Stress 104

image:

List of Tables

Table 1. Toxicity categories 7

Table 2. Recommended physical property test methods for PPE 28

TableS. Physical characteristics of glove materials 29

Table 4. Effect of thickness on the permeation of benzene through

neoprene rubber at 22°C 40

Table 5. Breakthrough times (minutes) for perchloroethylene,

p-Xylene, n-Butyl acetate, ethanol, and n-Hexane through

nitrile and neoprene gloves from several manufacturers 41

Table 6. Permeation of three two-component mixtures through

two glove materials 41

Table 7. Organic liquids used as carrier solvents in non-aqueous

solution pesticide formulations 45

Table 8. Ratings categories for qualitative summary of neat carrier

solvent permeation data 46

Table 9. Neat carrier solvent permeation table (ratings) 47

Table 10. Range of active ingredients and carrier solvents used in

EPA permeation study 51

Table 11. Glove materials used in EPA permeation study 51

Table 12. Individual ratings categories for qualitative summary

of EPA permeation data 52

Table 13. EPA study ratings 54

Table 14. Tracer ratings 59

Table 15. Sumary table 64

Table 16. Handwear selection guidance for protection for pesticide

formulations that contain organic solvents 69

Table 17. Body protection guidance 71

Table 18. Prices for hooded coveralls 76

Table 19. Selection guidance for eye and face protection 86

Table 20. Functional activities of mixers, loaders, and applications 92

Table 21. Weighting factors for functional requirements by

type of activity 96

Table 22. Protective clothing ensembles 96

Table 2 3. Increase in task time due to PPE 98

Table 24. Performance decrements as function of type of work

and protection level 101

Table 25. Overall performance decrements due to PPE 101

Table 26. Signs and Symptoms of Heat Stress 104

image:

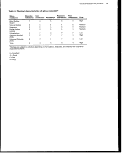

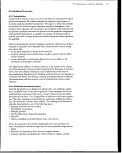

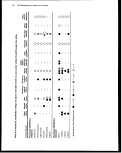

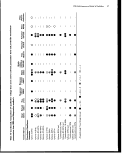

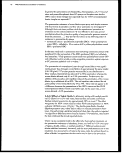

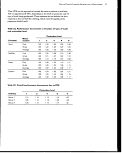

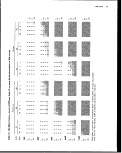

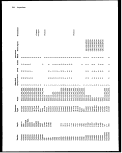

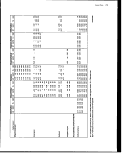

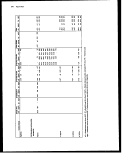

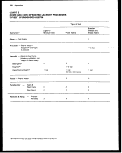

Table 2 7. Estimated work rates for agricultural activities 105

Table 2 8. Estimates of general work rates 106

Table 29. Thermal properties of fabrics used in clothing worn

by pesticide handlers 107

Table 30. Characteristics of heat stress models 110

Table 31. Examples of inputs used in heat stress prediction models 111

Table 32. Outputs from various heat stress models 111

Table 33. NIOSH recommended adjustments to threshold values

for clothing differences 115

Table 34. Estimated WBGT adjustments for five levels of pesticide

handler's clothing 115

Table 3 5. NIOSH recommended monitoring frequency 116

Table 36. Vital signs measurements 117

Table 37. Corrective action ny

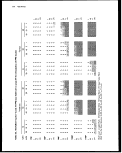

Table 3 8. Work/rest cycles—Level #1 PPE 118

Table 39. Work/rest cycles—-Level #2 PPE 119

Table 40. Work/rest cycles—Level #3 PPE 120

Table 41. Work/rest cycles—Level #4 PPE 121

Table 42. Metabolic rates for typical pesticide handlers activities 122

Table 43. Estimates of solar load (gain) on a black globe, btu/hr/ft2 124

Table 44. Association of PPE levels with pesticide handler activities 141

Table 45. Product appendices 142

Table 46. Approximate prices for chemical-resistant gloves 143

Table 47. Approximate prices for chemical-resistant sleeves 143

Table 48. Approximate prices for chemical-resistant aprons 144

Table 49. Approximate prices for jackets, pants, and coveralls 145

Table 50. Approximate prices for head protection 146

Table 51. Approximate prices for chemical-resistant footwear 146

image:

Table 2 7. Estimated work rates for agricultural activities 105

Table 2 8. Estimates of general work rates 106

Table 29. Thermal properties of fabrics used in clothing worn

by pesticide handlers 107

Table 30. Characteristics of heat stress models 110

Table 31. Examples of inputs used in heat stress prediction models 111

Table 32. Outputs from various heat stress models 111

Table 33. NIOSH recommended adjustments to threshold values

for clothing differences 115

Table 34. Estimated WBGT adjustments for five levels of pesticide

handler's clothing 115

Table 3 5. NIOSH recommended monitoring frequency 116

Table 36. Vital signs measurements 117

Table 37. Corrective action ny

Table 3 8. Work/rest cycles—Level #1 PPE 118

Table 39. Work/rest cycles—-Level #2 PPE 119

Table 40. Work/rest cycles—Level #3 PPE 120

Table 41. Work/rest cycles—Level #4 PPE 121

Table 42. Metabolic rates for typical pesticide handlers activities 122

Table 43. Estimates of solar load (gain) on a black globe, btu/hr/ft2 124

Table 44. Association of PPE levels with pesticide handler activities 141

Table 45. Product appendices 142

Table 46. Approximate prices for chemical-resistant gloves 143

Table 47. Approximate prices for chemical-resistant sleeves 143

Table 48. Approximate prices for chemical-resistant aprons 144

Table 49. Approximate prices for jackets, pants, and coveralls 145

Table 50. Approximate prices for head protection 146

Table 51. Approximate prices for chemical-resistant footwear 146

image:

Introduction

image:

Introduction

image:

image:

image:

1

Introduction

1.1 Pesticide Regulation

1.1.1 Current Role of the Environmeintal Protection Agency

The regulation of pesticides is mandated by Congress. Through its Office

of Pesticides Programs (OPP), the Environmental Protection Agency (EPA)

administers the Federal Insecticide, Fungicide, and Rodenticide Act

(FIFRA).

FIFRA was enacted in 1947 and required that pesticide products be regis-

tered with the U.S. Department of Agriculture (USDA) prior to marketing

in interstate commerce. In 1970, the EPA was established and the adminis-

tration of FIFRA was transferred from the USDA to the EPA. In 1972,

FIFRA was amended by the Federal Environmental Pesticide Control Act

(FEPCA), which broadened Federal regulatory authority by making it

"unlawful for any person to use any registered pesticide in a manner incon-

sistent with its labeling." The amendments required pesticide classification,

revised registration procedures, and established certification. They also

provided civil and criminal penalties for violations of the Act and authorized

cooperative enforcement agreements between the EPA and the States.

1.1.2 Office of Pesticide Programs Mission

The 1972 Congressional deliberations emphasized that EPA should imple-

ment FIFRA to protect workers (farmers, farm workers, and others) who

might be exposed to pesticides or their residues. EPAJs clear authority to

promulgate such requirements, including personal protective equipment

(PPE) standards designed to limit workers' exposure to pesticides and pesti-

cide residues, is well established in the legislative history and in the Courts.

1.1.3 Office of Pesticide Programs Involvement with Personal

Protective Equipment

In fulfillment of its responsibilities mandated by FIFRA, the EPA<s OPP

is currently involved in:

• Developing a consistent policy for PPE that will be applicable to all

aspects of the pesticide review process, including registrations of new

pesticides, re-registrations of pesticides, and pesticide decisions related

to human health concerns.

image:

1

Introduction

1.1 Pesticide Regulation

1.1.1 Current Role of the Environmeintal Protection Agency

The regulation of pesticides is mandated by Congress. Through its Office

of Pesticides Programs (OPP), the Environmental Protection Agency (EPA)

administers the Federal Insecticide, Fungicide, and Rodenticide Act

(FIFRA).

FIFRA was enacted in 1947 and required that pesticide products be regis-

tered with the U.S. Department of Agriculture (USDA) prior to marketing

in interstate commerce. In 1970, the EPA was established and the adminis-

tration of FIFRA was transferred from the USDA to the EPA. In 1972,

FIFRA was amended by the Federal Environmental Pesticide Control Act

(FEPCA), which broadened Federal regulatory authority by making it

"unlawful for any person to use any registered pesticide in a manner incon-

sistent with its labeling." The amendments required pesticide classification,

revised registration procedures, and established certification. They also

provided civil and criminal penalties for violations of the Act and authorized

cooperative enforcement agreements between the EPA and the States.

1.1.2 Office of Pesticide Programs Mission

The 1972 Congressional deliberations emphasized that EPA should imple-

ment FIFRA to protect workers (farmers, farm workers, and others) who

might be exposed to pesticides or their residues. EPAJs clear authority to

promulgate such requirements, including personal protective equipment

(PPE) standards designed to limit workers' exposure to pesticides and pesti-

cide residues, is well established in the legislative history and in the Courts.

1.1.3 Office of Pesticide Programs Involvement with Personal

Protective Equipment

In fulfillment of its responsibilities mandated by FIFRA, the EPA<s OPP

is currently involved in:

• Developing a consistent policy for PPE that will be applicable to all

aspects of the pesticide review process, including registrations of new

pesticides, re-registrations of pesticides, and pesticide decisions related

to human health concerns.

image:

Introduction

Specifying PPE performance data that must be provided by potential pes-

ticide registrants to support registration and re-registration applications.

Reviewing PPE performance data submitted to the Agency.

Resolving the status of new or continuing registration for pesticide prod-

ucts that threaten human health through the evaluation of PPE efficacy.

This assessment is based on factors related to the PPE (design, perform-

ance, decontamination, cost), the pesticide (toxicity, formulation, route

of entry) and the anticipated agricultural situation (task, duration, equip-

ment, and environment).

Developing product-specific PPE ensembles for inclusion on pesticide

labels as required attire for persons handling the product.

Developing a standard for PPE use and maintenance or agricultural pesti-

cide handlers and restricted-entry workers.

Developing guidance documents to support the Worker Protection Stan-

dard for Agricultural Workers, including information on decontamination

of PPE; selection of gloves, footwear, body protection, respirators, and eye

protection; and heat stress recognition, avoidance and alleviation.

Providing guidance on the protection performance of available types and

models of PPE.

Defending the EPAfc PPE decisions in a court of law, before Congress

and/or to the scientific community, including the EPA Scientific Advisory

Council.

1.1.4 Office of Research and Development's Personnel Protection

Program

The EPA established in the mid-1980s a Personnel Protection Technology

(PPT) Program within its Office of Research and Development (ORD). The

goal of the PPT Program is to focus and optimize the technology-related

aspects of the EPA-S PPT research, development, testing, evaluation, techni-

cal support, and training efforts. The Program is managed within ORD's

Risk Reduction Engineering Laboratory and has included internal projects

as well as extramural cooperative agreements, interagency agreements,

and contracts.

PPT is fundamental to the EPAJs regulatory and operational missions. PPT

includes gloves worn in the EPAs laboratories, robotic devices used at waste

sites, methods for minimizing the exposure of agricultural workers and pesti-

cides, and to mathematical models for predicting the chemical resistance of

clothing materials.

The EPA must have state-of-the-art PPT information with which to

develop, defend, and enforce its regulations. In particular, the Office of

Pesticides and Toxic Substances (OPTS) must be able to assess petitions for

the registration of new pesticides and premanufacture notifications (PMN)

for new chemicals. Furthermore, OPP must be able to transfer information

to the field in agricultural worker training programs. In some cases, the

fundamental data upon which to base worker protection regulations have

not been generated.

image:

Introduction

Specifying PPE performance data that must be provided by potential pes-

ticide registrants to support registration and re-registration applications.

Reviewing PPE performance data submitted to the Agency.

Resolving the status of new or continuing registration for pesticide prod-

ucts that threaten human health through the evaluation of PPE efficacy.

This assessment is based on factors related to the PPE (design, perform-

ance, decontamination, cost), the pesticide (toxicity, formulation, route

of entry) and the anticipated agricultural situation (task, duration, equip-

ment, and environment).

Developing product-specific PPE ensembles for inclusion on pesticide

labels as required attire for persons handling the product.

Developing a standard for PPE use and maintenance or agricultural pesti-

cide handlers and restricted-entry workers.

Developing guidance documents to support the Worker Protection Stan-

dard for Agricultural Workers, including information on decontamination

of PPE; selection of gloves, footwear, body protection, respirators, and eye

protection; and heat stress recognition, avoidance and alleviation.

Providing guidance on the protection performance of available types and

models of PPE.

Defending the EPAfc PPE decisions in a court of law, before Congress

and/or to the scientific community, including the EPA Scientific Advisory

Council.

1.1.4 Office of Research and Development's Personnel Protection

Program

The EPA established in the mid-1980s a Personnel Protection Technology

(PPT) Program within its Office of Research and Development (ORD). The

goal of the PPT Program is to focus and optimize the technology-related

aspects of the EPA-S PPT research, development, testing, evaluation, techni-

cal support, and training efforts. The Program is managed within ORD's

Risk Reduction Engineering Laboratory and has included internal projects

as well as extramural cooperative agreements, interagency agreements,

and contracts.

PPT is fundamental to the EPAJs regulatory and operational missions. PPT

includes gloves worn in the EPAs laboratories, robotic devices used at waste

sites, methods for minimizing the exposure of agricultural workers and pesti-

cides, and to mathematical models for predicting the chemical resistance of

clothing materials.

The EPA must have state-of-the-art PPT information with which to

develop, defend, and enforce its regulations. In particular, the Office of

Pesticides and Toxic Substances (OPTS) must be able to assess petitions for

the registration of new pesticides and premanufacture notifications (PMN)

for new chemicals. Furthermore, OPP must be able to transfer information

to the field in agricultural worker training programs. In some cases, the

fundamental data upon which to base worker protection regulations have

not been generated.

image:

Introduction

Under the Comprehensive Environmental Response, Compensation, and

Liability Act of 1980 (CERCLA or Superfund) and the Superfund Amend-

ments and Reauthorization Act of 1986 (SARA), EPA5s Regions I through X

and the Office of Solid Waste and Emergency Response either directly or

through their contractors are major consumers of PPT. Cost-effective

purchases of PPT require the EPA to know the range of products available.

In order to optimize the selection and use of PPT, the EPA must understand

the performance features and limitations of PPT. In those cases where it has

unique needs, the EPA has the opportunity to develop or specify new prod-

ucts and procedures. To do so, however, requires insights into PPT science

and engineering.

This Guidance Manual is one product of the PPT Program to address these

needs and is specifically responsive to OPP's PPT needs as described in

Section 1.1.3.

1.2 Purpose of Guidance Manual

The primary purpose of the Guidance Manual for Selecting Protective Clothing

for Agricultural Pesticides Operations is to provide technical information and

guidance to the OPP personnel who formulate PPE standards, decisions,

and recommendations for persons who handle pesticides.

The secondary purpose of this Guidance Manual is as a source for technical

information and guidance that will be transferred to persons who interpret

the EPA!s PPE standards, explaining or conveying the EPAJs PPE decisions

and advising agricultural pesticide handlers in the appropriate selection, use,

and maintenance of PPE. These persons include:

• government and Cooperative Extension Service personnel in states, tribes,

and territories;

• pesticide manufacturers, formulators, registrants, and dealers; and

• advisors and trainers of agricultural pesticide users.

1.3 Guidance Manual Content

The Guidance Manual has nine sections. The sections may be read sequen-

tially if the reader wants a comprehensive understanding of current, pesticide-

related PPE data or guidance on the interpretation of those data as it applies

to agricultural situations involving pesticide mixers/loaders/applicators. Readers

may also refer to one chart or subsection for immediate details about a particular

topic or item of PPE. A single-page Section in Brief precedes the body of each

section. These pages highlight and summarize the key information contained

in the sections. ~—

The nine sections are:

• Introduction. Section 1 explains the authority and administrative responsi-

bilities of the EPA!s OPP. It discusses the Guidance Manual's purpose and

content.

image:

Introduction

Under the Comprehensive Environmental Response, Compensation, and

Liability Act of 1980 (CERCLA or Superfund) and the Superfund Amend-

ments and Reauthorization Act of 1986 (SARA), EPA5s Regions I through X

and the Office of Solid Waste and Emergency Response either directly or

through their contractors are major consumers of PPT. Cost-effective

purchases of PPT require the EPA to know the range of products available.

In order to optimize the selection and use of PPT, the EPA must understand

the performance features and limitations of PPT. In those cases where it has

unique needs, the EPA has the opportunity to develop or specify new prod-

ucts and procedures. To do so, however, requires insights into PPT science

and engineering.

This Guidance Manual is one product of the PPT Program to address these

needs and is specifically responsive to OPP's PPT needs as described in

Section 1.1.3.

1.2 Purpose of Guidance Manual

The primary purpose of the Guidance Manual for Selecting Protective Clothing

for Agricultural Pesticides Operations is to provide technical information and

guidance to the OPP personnel who formulate PPE standards, decisions,

and recommendations for persons who handle pesticides.

The secondary purpose of this Guidance Manual is as a source for technical

information and guidance that will be transferred to persons who interpret

the EPA!s PPE standards, explaining or conveying the EPAJs PPE decisions

and advising agricultural pesticide handlers in the appropriate selection, use,

and maintenance of PPE. These persons include:

• government and Cooperative Extension Service personnel in states, tribes,

and territories;

• pesticide manufacturers, formulators, registrants, and dealers; and

• advisors and trainers of agricultural pesticide users.

1.3 Guidance Manual Content

The Guidance Manual has nine sections. The sections may be read sequen-

tially if the reader wants a comprehensive understanding of current, pesticide-

related PPE data or guidance on the interpretation of those data as it applies

to agricultural situations involving pesticide mixers/loaders/applicators. Readers

may also refer to one chart or subsection for immediate details about a particular

topic or item of PPE. A single-page Section in Brief precedes the body of each

section. These pages highlight and summarize the key information contained

in the sections. ~—

The nine sections are:

• Introduction. Section 1 explains the authority and administrative responsi-

bilities of the EPA!s OPP. It discusses the Guidance Manual's purpose and

content.

image:

Introduction

• Handling Pesticides. Section 2 describes the range of handler activities,

formulations options, exposure scenarios, environmental factors, and facility

amenities as they relate to mixing, loading, and applying pesticides. Routine

pesticide-handling tasks are dissected into procedural steps to help readers

evaluate the risk of exposure, the need for protective equipment, and the

potential effect of PPE on job performance.

• Chemical-Resistant PPE Products. Section 3 describes PPE types and

emphasizes the importance of garment design and construction. Particular

attention is given to hand protection and coveralls; aprons, head protec-

tion, and footwear are also included. This information is keyed to extensive

appendices that describe types and brands of PPE and their sources.

• PPE Performance as a Barrier to Pesticides. Section 4 defines the terminol-

ogy and procedures for evaluating glove and garment materials as barriers

to pesticides. Recommendations for hand/arm and body protection relate

the material properties to the formulation and ingredients of the pesticides.

• Eye and Face Protection. Section 5 reviews the characteristics of eye and

face protectors that are suitable for the various forms of pesticides. The test

is supplemented by an appendix that lists commercially available products.

• Effect of Personal Protective Equipment on Job Performance. Section 6

recognizes that protective equipment may reduce worker productivity or

introduce additional safety problems. An approach is introduced for quan-

titatively assessing the magnitude of these effects pertinent to hand dexter-

ity and tactility, mobility, vision, and speech intelligibility is assessed.

• Heat Stress. Section 7 addresses the role of protective equipment in

heat-related illnesses. The problem is defined and sensible practices for

avoiding or alleviating heat stress are outlined.

• PPE Selection and Use Process. Section 8 helps readers relate the infor-

mation in earlier sections to actual pesticide situations and individual

decision-making. A step-by-step process is given for PPE selection, use,

and disposal.

• Decontamination/Laundering. Section 9 focuses on the decontamination

of reusable protective equipment. It emphasizes the importance of proper

maintenance and the risk of secondary exposure through pesticide transfer

from contaminated clothing. Decontamination processes are discussed in

terms of fabrics, detergents, temperature, water, timeliness, and fabric

finishes.

image:

Introduction

• Handling Pesticides. Section 2 describes the range of handler activities,

formulations options, exposure scenarios, environmental factors, and facility

amenities as they relate to mixing, loading, and applying pesticides. Routine

pesticide-handling tasks are dissected into procedural steps to help readers

evaluate the risk of exposure, the need for protective equipment, and the

potential effect of PPE on job performance.

• Chemical-Resistant PPE Products. Section 3 describes PPE types and

emphasizes the importance of garment design and construction. Particular

attention is given to hand protection and coveralls; aprons, head protec-

tion, and footwear are also included. This information is keyed to extensive

appendices that describe types and brands of PPE and their sources.

• PPE Performance as a Barrier to Pesticides. Section 4 defines the terminol-

ogy and procedures for evaluating glove and garment materials as barriers

to pesticides. Recommendations for hand/arm and body protection relate

the material properties to the formulation and ingredients of the pesticides.

• Eye and Face Protection. Section 5 reviews the characteristics of eye and

face protectors that are suitable for the various forms of pesticides. The test

is supplemented by an appendix that lists commercially available products.

• Effect of Personal Protective Equipment on Job Performance. Section 6

recognizes that protective equipment may reduce worker productivity or

introduce additional safety problems. An approach is introduced for quan-

titatively assessing the magnitude of these effects pertinent to hand dexter-

ity and tactility, mobility, vision, and speech intelligibility is assessed.

• Heat Stress. Section 7 addresses the role of protective equipment in

heat-related illnesses. The problem is defined and sensible practices for

avoiding or alleviating heat stress are outlined.

• PPE Selection and Use Process. Section 8 helps readers relate the infor-

mation in earlier sections to actual pesticide situations and individual

decision-making. A step-by-step process is given for PPE selection, use,

and disposal.

• Decontamination/Laundering. Section 9 focuses on the decontamination

of reusable protective equipment. It emphasizes the importance of proper

maintenance and the risk of secondary exposure through pesticide transfer

from contaminated clothing. Decontamination processes are discussed in

terms of fabrics, detergents, temperature, water, timeliness, and fabric

finishes.

image:

Handling Pesticides

image:

Handling Pesticides

image:

image:

image:

2

The Section in Brief

In establishing personal protective equipment (PPE) requirements and work

safety practices, regulators must strive for a balance between the goal of

reducing risks to pesticide handlers and the reality of the limitations and

complexities imposed by the agricultural workplace environment.

Establishing general personal protective equipment guidelines for handlers

of agricultural pesticides is complicated by the vast range of activities encom-

passed by the term agriculture. Agriculture includes not only traditional

row-crop farming, but also activities relating to livestock, poultry, pasture

and rangeland, forests, nurseries, and greenhouses.

Even within these general categories of agriculture, there is wide variation in

individual workplace environments. Nevertheless, there are several elements

basic to every agricultural situation that affect PPE decisions:

• Handling activities—Users of agricultural pesticides, through mixing,

loading, and application, perform many activities that involve direct expo-

sure to the pesticides.

« Formulation characteristics—Appropriate PPE depends on pesticide

form, toxicity, concentration, carrier solvents, and other inert ingredients.

• Exposure scenarios—The particular work situation affects not only the

potential for exposure to pesticides, but also the potential for heat stress—

an important factor to consider when managing the use of PPE. Pesticide

handlers may be on foot, in a vehicle, or in an aircraft. They may have the

benefit of engineering controls, or their risk may be increased because

they are working in enclosed areas.

• Environmental factors—Weather conditions, including temperature,

humidity, wind, and sunlight, can strongly influence the PPE selection

process and the work regimen of pesticide handlers. If the work is particu-

larly vigorous or the terrain is rough, the durability of the PPE may be

more important than its chemical resistance.

image:

2

The Section in Brief

In establishing personal protective equipment (PPE) requirements and work

safety practices, regulators must strive for a balance between the goal of

reducing risks to pesticide handlers and the reality of the limitations and

complexities imposed by the agricultural workplace environment.

Establishing general personal protective equipment guidelines for handlers

of agricultural pesticides is complicated by the vast range of activities encom-

passed by the term agriculture. Agriculture includes not only traditional

row-crop farming, but also activities relating to livestock, poultry, pasture

and rangeland, forests, nurseries, and greenhouses.

Even within these general categories of agriculture, there is wide variation in

individual workplace environments. Nevertheless, there are several elements

basic to every agricultural situation that affect PPE decisions:

• Handling activities—Users of agricultural pesticides, through mixing,

loading, and application, perform many activities that involve direct expo-

sure to the pesticides.

« Formulation characteristics—Appropriate PPE depends on pesticide

form, toxicity, concentration, carrier solvents, and other inert ingredients.

• Exposure scenarios—The particular work situation affects not only the

potential for exposure to pesticides, but also the potential for heat stress—

an important factor to consider when managing the use of PPE. Pesticide

handlers may be on foot, in a vehicle, or in an aircraft. They may have the

benefit of engineering controls, or their risk may be increased because

they are working in enclosed areas.

• Environmental factors—Weather conditions, including temperature,

humidity, wind, and sunlight, can strongly influence the PPE selection

process and the work regimen of pesticide handlers. If the work is particu-

larly vigorous or the terrain is rough, the durability of the PPE may be

more important than its chemical resistance.

image:

Facility amenities—Provisions for personal decontamination and cleaning

of PPE vary widely. At some remote work sites, the only source of clean

wash water is a nearby stream. Only large corporate agricultural establish-

ments are likely to provide health monitoring for pesticide exposure and

for heat stress symptoms.

image:

Facility amenities—Provisions for personal decontamination and cleaning

of PPE vary widely. At some remote work sites, the only source of clean

wash water is a nearby stream. Only large corporate agricultural establish-

ments are likely to provide health monitoring for pesticide exposure and

for heat stress symptoms.

image:

2

Handling Pesticides

2.1 Introduction

The factors that influence selection decisions regarding personal protective

equipment (PPE) and associated workplace safety practices for pesticide

handlers are particularly complex hi the agricultural setting. The range of

handler activities, formulation options, exposure scenarios, environmental

factors, and facility amenities is vast. The term "agriculture" often conjures

the image of tractors with booms traversing fields of crops neatly planted

in parallel rows. This is an unfortunate misconception. In addition to

traditional row-crop farming, the generic term "agriculture" also typically

includes activities relating to livestock, poultry, pasture and rangeland,

forests, nurseries, and greenhouses. To guide or regulate the selection and

use of PPE for the various circumstances of these diverse industries, a clear

understanding of pesticide-handling tasks is needed.

2.2 Handling Activities

Users of agricultural pesticides perform many activities that involve direct

exposure to these chemicals. Adequate PPE selection guidelines must

address the range of pesticide-handling jobs and the associated exposure

risks. To simplify and focus this discussion, the various pesticide activities

will be described under three main operations: mixing, loading, and

application.

2.2.1 Mixing pesticides

Activities associated with mixing pesticides include:

• transferring pesticide from original container to mixing or application

tank or hopper and adding diluent

• conveying open pesticide containers to and from use site

• containing or cleaning up a pesticide spill

• washing contaminated equipment after use

• disposing of pesticide containers

• repairing contaminated mixing equipment such as leaking or broken hoses

image:

2

Handling Pesticides

2.1 Introduction

The factors that influence selection decisions regarding personal protective

equipment (PPE) and associated workplace safety practices for pesticide

handlers are particularly complex hi the agricultural setting. The range of

handler activities, formulation options, exposure scenarios, environmental

factors, and facility amenities is vast. The term "agriculture" often conjures

the image of tractors with booms traversing fields of crops neatly planted

in parallel rows. This is an unfortunate misconception. In addition to

traditional row-crop farming, the generic term "agriculture" also typically

includes activities relating to livestock, poultry, pasture and rangeland,

forests, nurseries, and greenhouses. To guide or regulate the selection and

use of PPE for the various circumstances of these diverse industries, a clear

understanding of pesticide-handling tasks is needed.

2.2 Handling Activities

Users of agricultural pesticides perform many activities that involve direct

exposure to these chemicals. Adequate PPE selection guidelines must

address the range of pesticide-handling jobs and the associated exposure

risks. To simplify and focus this discussion, the various pesticide activities

will be described under three main operations: mixing, loading, and

application.

2.2.1 Mixing pesticides

Activities associated with mixing pesticides include:

• transferring pesticide from original container to mixing or application

tank or hopper and adding diluent

• conveying open pesticide containers to and from use site

• containing or cleaning up a pesticide spill

• washing contaminated equipment after use

• disposing of pesticide containers

• repairing contaminated mixing equipment such as leaking or broken hoses

image:

6 Handling Pesticides

2.2.2 Loading pesticides

Loading activities include:

• transferring pesticide from mixing apparatus to application equipment

• conveying open pesticide containers to and from use site

• containing or cleaning up a pesticide spill

• washing contaminated equipment after use

• repairing contaminated loading equipment

2.2.3 Applying pesticides

Applying pesticides may involve:

• On foot

- using hand-held sprayers or shake cans

- using backpack or knapsack sprayers or dusters

— using portable, aerosol generators or foggers

- pushing or pulling wheel-mounted sprayers

- using high-pressure, handgun nozzles

- using hand-held, fumigation equipment

- using dipping vats or spray-dip machine

- putting plants or seeds in pesticides

- flagging for aircraft applications

- repairing contaminated application equipment such as clogged nozzles,

leaking or broken hoses, or other malfunctions that occur when the

equipment is in use

- adjusting contaminated application equipment such as adjusting boom

height, adjusting nozzle pattern, or adjusting hopper openings

— containing or cleaning up a pesticide spill

- disposing of excess pesticide

- washing contaminated equipment after use

• By vehicle

— pulling or mounted with a low-pressure sprayer

— pulling or mounted with a boom

- pulling or mounted with a granular applicator

- pulling or mounted with a high-pressure sprayer

- pulling or mounted with injector or incorporator

- pulling or mounted with a fumigation applicator

- pulling or mounted with a power duster

— pulling or mounted with an aerosol generator or fogger

- pulling or mounted with an airblast sprayer

• By air

- using aircraft with open cockpits

— using aircraft with enclosed cockpits

2.3 Formulation Characteristics

The range of pesticide formulations routinely used in agricultural situations

complicates the selection of appropriate PPE. Pesticide form, toxicity,

concentration, and additives and inert ingredients are primary considerations

in planning clothing strategies.

image:

6 Handling Pesticides

2.2.2 Loading pesticides

Loading activities include:

• transferring pesticide from mixing apparatus to application equipment

• conveying open pesticide containers to and from use site

• containing or cleaning up a pesticide spill

• washing contaminated equipment after use

• repairing contaminated loading equipment

2.2.3 Applying pesticides

Applying pesticides may involve:

• On foot

- using hand-held sprayers or shake cans

- using backpack or knapsack sprayers or dusters

— using portable, aerosol generators or foggers

- pushing or pulling wheel-mounted sprayers

- using high-pressure, handgun nozzles

- using hand-held, fumigation equipment

- using dipping vats or spray-dip machine

- putting plants or seeds in pesticides

- flagging for aircraft applications

- repairing contaminated application equipment such as clogged nozzles,

leaking or broken hoses, or other malfunctions that occur when the

equipment is in use

- adjusting contaminated application equipment such as adjusting boom

height, adjusting nozzle pattern, or adjusting hopper openings

— containing or cleaning up a pesticide spill

- disposing of excess pesticide

- washing contaminated equipment after use

• By vehicle

— pulling or mounted with a low-pressure sprayer

— pulling or mounted with a boom

- pulling or mounted with a granular applicator

- pulling or mounted with a high-pressure sprayer

- pulling or mounted with injector or incorporator

- pulling or mounted with a fumigation applicator

- pulling or mounted with a power duster

— pulling or mounted with an aerosol generator or fogger

- pulling or mounted with an airblast sprayer

• By air

- using aircraft with open cockpits

— using aircraft with enclosed cockpits

2.3 Formulation Characteristics

The range of pesticide formulations routinely used in agricultural situations

complicates the selection of appropriate PPE. Pesticide form, toxicity,

concentration, and additives and inert ingredients are primary considerations

in planning clothing strategies.

image:

Handling Pesticides

2.3.1 Form

Agricultural pesticides exist in a variety of forms: gases, liquids, emulsions,

granules, powders, pellets, aerosols, encapsulates, and even impregnated

materials such as wax bars and wiper wicks. Each type of formulation may

require distinct strategies for protecting pesticide handlers with PPE.

Liquids may splash or slosh during mixing and loading, causing a potential

exposure through ocular, dermal, and oral routes. Furthermore, until

sprays have dried, such formulations have the potential to soak through

non-chemical-resistant materials, creating dermal exposure. Due to per-

spiration, they may penetrate even after drying.

Dry formulations often cause clouds or puffs of powdery pesticide to waft

upward during mixing and loading, causing potential exposure through

ocular, dermal, and inhalation routes. Persons exposed to dry formulations

may be unaware that pesticides have penetrated their clothing or equipment,

because they do not sense "wetting through."

Gas formulations have obvious exposure potential through the inhalation

route, but some also present an exposure risk through the dermal route.

Exposure may occur if the gases become trapped in clothing made of fabrics

or materials having low air permeability.

2.3.2 Toxicity

In general, the greater the pesticide toxicity, the greater the amount of

protection needed by the worker. Tbxicity categories (Table 1) are based on

the LDso, a statistical estimate of a chemical dose which, when administered,

will kill 50 percent of the test animals within a stated period of observation.

Table 1. Toxicity categories

Category

1

II

III

Toxicity

Highly toxic

Moderately toxic

Slightly toxic

Siignal word

Danger

Warning

Caution

Correlating PPE recommendations with the pesticide toxicity categories

is helpful for the pesticide user accustomed to reading signal words on the

product labels. One complication, however, is that a single pesticide may be

ranked as Category I for oral toxicity and as Category IE for dermal toxicity.

A second complication is the duration of the exposure. Pesticide handlers

may mistakenly believe they do not need protective equipment because they

are using pesticides of low toxicity. In fact, longterm exposure to slightly

toxic pesticides can sometimes be as dangerous as a brief exposure to a highly

toxic pesticide.

image:

Handling Pesticides

2.3.1 Form

Agricultural pesticides exist in a variety of forms: gases, liquids, emulsions,

granules, powders, pellets, aerosols, encapsulates, and even impregnated

materials such as wax bars and wiper wicks. Each type of formulation may

require distinct strategies for protecting pesticide handlers with PPE.

Liquids may splash or slosh during mixing and loading, causing a potential

exposure through ocular, dermal, and oral routes. Furthermore, until

sprays have dried, such formulations have the potential to soak through

non-chemical-resistant materials, creating dermal exposure. Due to per-

spiration, they may penetrate even after drying.

Dry formulations often cause clouds or puffs of powdery pesticide to waft

upward during mixing and loading, causing potential exposure through

ocular, dermal, and inhalation routes. Persons exposed to dry formulations

may be unaware that pesticides have penetrated their clothing or equipment,

because they do not sense "wetting through."

Gas formulations have obvious exposure potential through the inhalation

route, but some also present an exposure risk through the dermal route.

Exposure may occur if the gases become trapped in clothing made of fabrics

or materials having low air permeability.

2.3.2 Toxicity

In general, the greater the pesticide toxicity, the greater the amount of

protection needed by the worker. Tbxicity categories (Table 1) are based on

the LDso, a statistical estimate of a chemical dose which, when administered,

will kill 50 percent of the test animals within a stated period of observation.

Table 1. Toxicity categories

Category

1

II

III

Toxicity

Highly toxic

Moderately toxic

Slightly toxic

Siignal word

Danger

Warning

Caution

Correlating PPE recommendations with the pesticide toxicity categories

is helpful for the pesticide user accustomed to reading signal words on the

product labels. One complication, however, is that a single pesticide may be

ranked as Category I for oral toxicity and as Category IE for dermal toxicity.

A second complication is the duration of the exposure. Pesticide handlers

may mistakenly believe they do not need protective equipment because they

are using pesticides of low toxicity. In fact, longterm exposure to slightly

toxic pesticides can sometimes be as dangerous as a brief exposure to a highly

toxic pesticide.

image:

8 Handling Pesticides

2.3.3 Concentration

Agricultural pesticide handlers usually are exposed to highly concentrated

pesticides during the mixing and loading process. Mixers/loaders of pesti-